A reliable product.

Progressive thinking

Innovation with regard to water recycling and disinfection, logistics processes, plus heat and CO2 use all play a central role at all Beekenkamp production sites. With 18 ha of modern greenhouses in the Netherlands, we produce young plants of the highest possible quality.

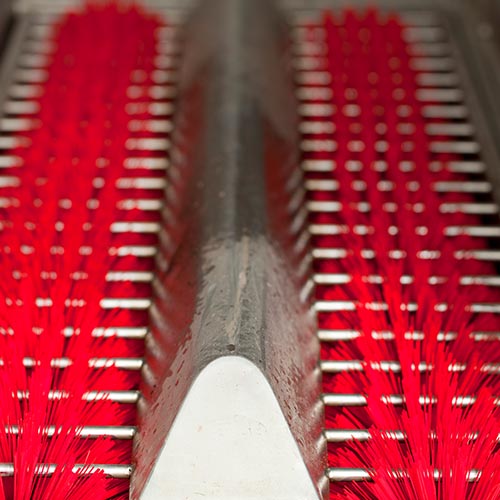

Strict hygiene

Our strict hygiene measures apply not only to our propagation greenhouses but also to our personnel, containers and vehicles. Our quality inspectors check all processes on a daily basis and test the health and quality of our starting material in the laboratory.

Breeding - the best selection

In collaboration with growers, wholesalers, retailers and supply chain partners, our breeders work day-in day-out on new, robust varieties, including Poinsettia, Begonia, Dahlia, Celosia, Lavandula and Campanula. From crop improvement to unique products such as our Begonia Evi and the acclaimed TomTato®.

Emissieproof met de Opticlear Diamond

Beekenkamp recycles the water for young plants for 100%. If the EC grows too high for one crop, some of the water goes to a crop that can use a higher EC.

For degradation of plant protection products and inhibitor, UV light in combination with H2O2 turned out to be insufficient. Complete disinfection and disposal of residues of plant protection products are achieved with the OPTICLEAR DIAMOND. In this way we meet the emission requirements and the increasing quality requirements of customers.

LED cells

A few years ago Beekenkamp started developing LED cells. Certhon and Beekenkamp discussed about how they can use LED in the cultivation of ornamental and fruit crops. Last year 8 climate cells were delivered in which make us very flexible in controlling the climate. We use water-cooled LED lamps in the cells. The water flows through the lamps so the heat is immediately removed. The water that is released in this process is negligible.